Hot-dip galvanized square tube is a square tube made of steel plate or steel strip after being rolled and welded. After a series of chemical reactions in the hot-dip galvanizing bath, the square tube is formed; it can also be hot-rolled or cold-rolled galvanized steel. A hollow square section steel pipe made by cold bending and high frequency welding. The production process of hot-dip galvanized square pipe is simple, the production efficiency is high, there are many varieties and specifications, and the equipment investment is small, but the strength is generally lower than that of seamless square pipe.

Hot-dip galvanized square pipe is divided into seamless and welded seam. Seamless square pipe is formed by extruding seamless round pipe.

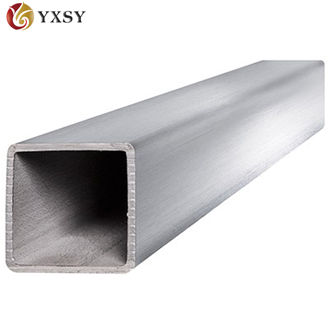

The surface of hot-dip galvanized square tube is bright and beautiful, which can be directly used in engineering according to demand. Hot-dip galvanized square pipe is generally judged by the appearance of the product to be qualified. If there are missing plating, pitting, white spots, heavy skin, bubbles, greenishness and excessive frequency on the outer surface of the square pipe, it is judged as unqualified product. However, in the product standard, there is a prescribed range for the deviation of the product, that is, the "allowable deviation" of the size.

Due to its excellent performance, hot-dip galvanized square pipes are often used in glass curtain walls, power towers, telecommunications grids, water and gas transmission, wire casings, houses, bridges, metal structures, and power transmission. Ground is adopted.

Since the 1930s, with the rapid development of high-quality hot-dip galvanized square pipe production and the improvement of welding and inspection technology, the quality of welds has been continuously improved, the variety of welded steel pipes has increased, and they have replaced in more and more fields Seamless steel pipe.