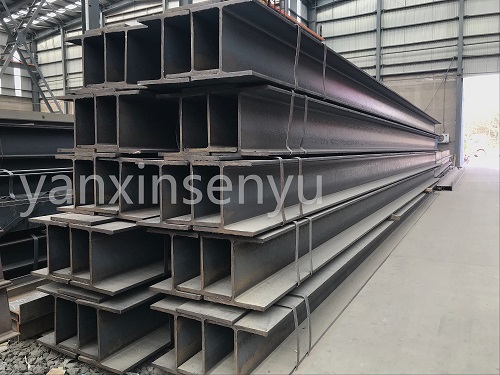

Everyone knows that H-shaped steel is a long steel with an I-shaped cross section. H-shaped steel is a very widely used steel. It can now be used in bridges, building structures, vehicles, supports, machinery and other fields.

Because the production process of H-beam is relatively complicated, for example, in the production process, quenching requires many different steps, let the Laiwu H-beam manufacturer briefly introduce its quenching process for everyone.

Quenching cooling, during the cooling process of H-shaped steel workpieces, there is a certain difference in the cooling rate between the surface and the core. If this difference is large enough, it is likely to cause a portion greater than the critical cooling rate to transform into martensite. Case where the critical cooling rate heart cannot be transformed into martensite.

Quenching insulation, quenching holding time is determined by various factors such as equipment heating method, part size, steel composition and equipment power. For the overall quenching, the main purpose of heat insulation is to make the internal temperature of the workpiece uniform and uniform, and to heat-harden H-shaped steel The time ultimately depends on obtaining a good quenched heating structure in the area where quenching is required.

H-shaped steel is a high-efficient and economical cross-section steel. It can not only play a higher role in the process of use, but also has a higher bearing capacity, so it is a profile that is currently loved by users.