We all know that different steels have different characteristics, and under the circumstances of rapid changes in steel technology, the advantages of new high-frequency welding H-beams have begun to outweigh those of ordinary I-beams, so let's look at the differences between them.

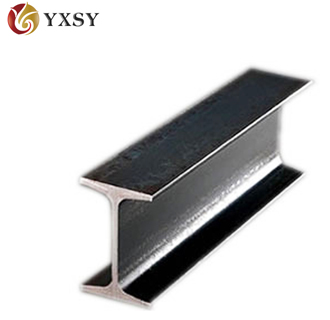

H-Beam

First of all, welded H-shaped steel is a widely used profile in today's steel structure buildings, such as factory buildings, high-rise buildings and bridges, ships, supports, equipment foundations, lifting and transportation machinery, and foundation piles. From the appearance characteristics of the two steels, the flange of the high-frequency welding H-beam is wider than the ordinary I-beam, and the slope is smaller than it. Because the cross-section characteristics are better than the ordinary I-beam, the high-frequency welding H-beam is applicable The scope is wider.

I-Beam

Furthermore, the high-frequency welded H-shaped steel has a reasonable cross-sectional shape and the inner and outer surfaces are parallel, so the cutting capacity is stronger. The ordinary I-shaped steel has a relatively high and narrow cross-sectional size, which makes it suitable for use in applications. Considerable irrationality and limitations.

I- Beam

Then there is the production process of the two. The high-frequency welding H-beam adopts the universal rolling process. The rolling process and equipment are more complicated than ordinary rolling mills. Due to this complexity, the models produced are more complete, which is beneficial to the design time. Pick a variety of different models.

Their weldability, because high-frequency welding H-beam is a type of welded steel, it can meet the requirements of scheduled service requirements, and is not prone to cracks and pores. Has high mechanical properties. The ordinary I-shaped steel is directly rolled, and it has no welds, which is not convenient for construction applications.