There are more and more manufacturers of hot-dip galvanized steel springboards, and the market demand is also higher. The quality of products on the market is high or low, but only products with quality requirements can ensure safety. Hot-dip galvanized steel springboards are used in the construction industry. In order to ensure the correct implementation of the building, it is necessary to choose good quality products. What are the factors related to the quality of hot-dip galvanized steel springboard?

One: steel material. There is a fundamental difference between the hardness of steel in small steel mills and big steel mills. Some small steel mills cannot meet the requirements of materials and crack in a few months, affecting the service life of steel springboards. However, the materials of large steel mills are guaranteed and the production technology is relatively high.

Two: steel plate thickness. The thickness of the plate determines the age of the steel springboard. If your construction period is shorter, within 1-2 years, then you should use a plate with a thickness of 1.2MM; if you are a rental station or you need to use 6-8 years, then use a plate thickness of 1.5MM. On the basis of controlling raw materials, such a plate thickness is enough for you to use.

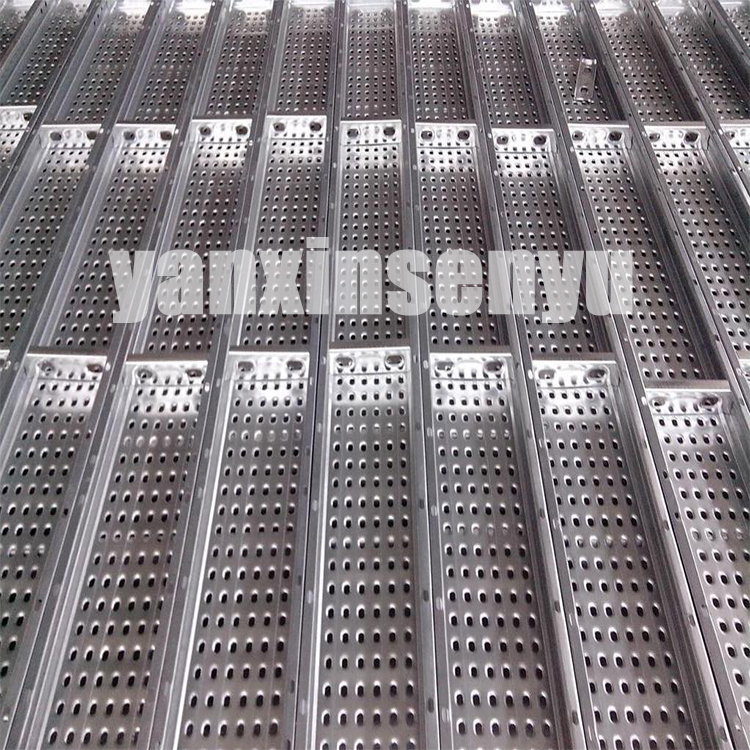

Three: hot-dip galvanized steel springboard process: the design and production mode of steel springboard have great influence on its performance. The steel springboard produced by us has reasonable design, anti-slip, fastening, corrosion-resistant and wear-resistant, not easy to damage, durable and safe. Reliable, has been loved by the majority of users.

The above is some of the influencing factors on the quality of hot-dip galvanized steel springboard. In fact, there are many other factors that affect the quality of hot-dip galvanized steel springboard. Xiaobian is not listed here for you. The important points are already I will explain it to you and hope to help everyone!