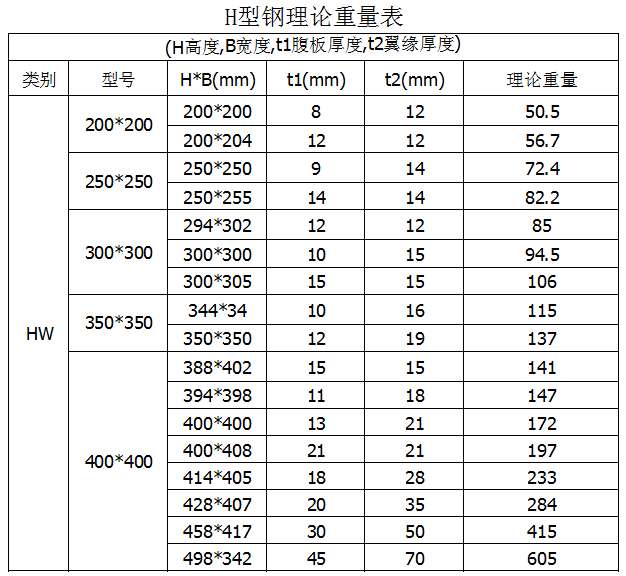

H-shaped steel section similar to uppercase letter H, also known as universal steel beams.The cross section of the H-beam usually consists of two parts, the web and the flange plate, also known as the waist and the edge.There are many specifications of H-beam, the specific specifications are as follows:

After understanding the commonly used H-beam specifications, we come to understand the effect of the construction of H-beam:

1.The first step in the production of H-beam member is staked under the material, if the Component Processing quality below standard, it will make the construction work is affected, resulting in building quality problems, so the H-beam cutting, must be strictly in accordance with the drawings.

2.H-beam connection there are three main: first, the welding of steel, the second is bolted, the third is the rivet connection, in which the main components of the production of welding, welding quality related to the quality of the entire building, so the need for professional welding personnel to complete the welding work, must be full of welding, non-leak welding.

3.H-shaped steel building is the biggest feature of Assembly, in the factory processed components, directly transported to the construction site for installation.If the quality of the installation in the event of a problem, not only the quality of the entire project greatly reduced, but also may cause on-site construction accident, so the installation should follow the process steps to ensure the stability of H-beam engineering reinforcement.

4.H-shaped steel fire and corrosion resistance in general, so the components should be done in the processing of fire-resistant paint and anti-corrosion coating paint, paint coating to avoid uneven thickness, surface sagging phenomenon.