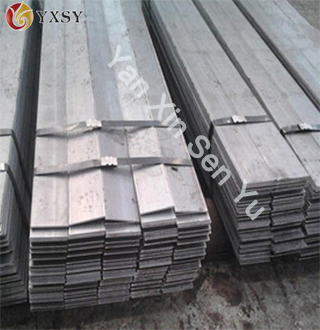

Flat steel manufacturers tell you that cold drawn flat steel has extrusion deformation and extrusion deformation, which is usually carried out on a special cold drawing machine. The material of the cold drawn flat steel is better than the material of the cold drawn flat steel. If you want to make cold drawn flat steel have better use, you need to do some strengthening treatment.

1. Material processing by flat steel manufacturers. The material products are all cold drawn flat steels which have higher dimensional accuracy requirements. The processing can determine the dimensional accuracy and surface brightness of the processed products by selecting the size of the materials. Generally, the outer diameter of the products is larger than the required outer diameter. a few millimeters of material to process;

2, drawing processing. After the raw materials are processed in the early stage, they can be processed on the machine. In order to reduce the loss of the drawing die, the mold must be lubricated in this process. There are generally two methods of lubrication, one is oil lubrication and the other is special lubrication material. lubricating;

3, flat steel manufacturers processing. It mainly includes the straightening processing, the removal of the chuck waste processing, the cut-to-length cutting, and the anti-rust treatment.

Regarding the strengthening treatment of this cold-drawn flat steel by flat steel manufacturers, the text has already been explained clearly. In the future operation, everyone should know more about the product knowledge, in order to better facilitate their own operation and application. Explain the knowledge of the intensive processing, and you can use the specific application in the future operation.